- 0 Comments

- admin

- November 6, 2020

The COVID-19 pandemic has emphasized the criticality of a resilient and efficient supply chain fulfillment lifecycle. The ongoing situation has forced businesses to relook at their supply chains and fulfilment operations and question the efficacy of existing processes and practices. Status quo is passé today. What are the implications for a business?

In May 2020, a survey found that 93% of respondents desired to improve their supply chain resilience in the coming months. A case in point is the retail and e-commerce segments where online sales have surged and expected to increase by almost 20% in the US this year. Distribution centers and eCommerce fulfillment centers are struggling to handle the increase. Not only has the number of orders increased, the complexity, variety of products and delivery speed have also risen. In this context, warehouses play a critical role in helping retailers and eCommerce firms deliver to the customer in a timely and satisfactory manner.

Clearly, for businesses to survive and thrive, they must accept the “now is normal” and adapt to the changing situation swiftly.

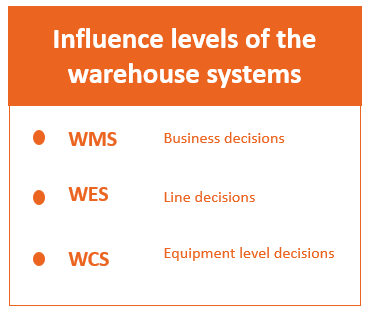

Understanding the role of a warehouse management system (WMS), warehouse execution system (WES) and warehouse control system (WCS) in this context is therefore essential. Gaining an understanding of the function of each of these systems helps determine the most suitable one for your operating environment.

What do these systems do?

WMS

A software solution that has been in use for a while, the WMS mainly controls the effective movement of warehouse inventory. Especially relevant in the eCommerce world, it books orders, forecasts, manages inventory and even interfaces with the customer front-end. A WMS takes decisions at the warehouse level and cannot communicate at the machine level.

WES

A WES can manage multiple lines and multiple automation processes within a line, including some of WMS and all aspects of WCS. Investment in WES alone may suffice for small to medium-sized retailers to automate their operations and improve their performance.

WCS

With a narrower focus, the WCS orchestrates the automation and movement of individual items such as cartons and pallets. Automation can be in the form of AS/RS, conveyors, goods-to-person systems, sorters, decasing lines and so on. Operating on top of the PLC, a WCS takes warehouse-level instructions and converts it to machine-level instructions and vice-versa, all in real-time. In this way, it optimizes investment by integrating real-time operations intelligence into the warehouse processes.

How do they work together?

How do they work together?

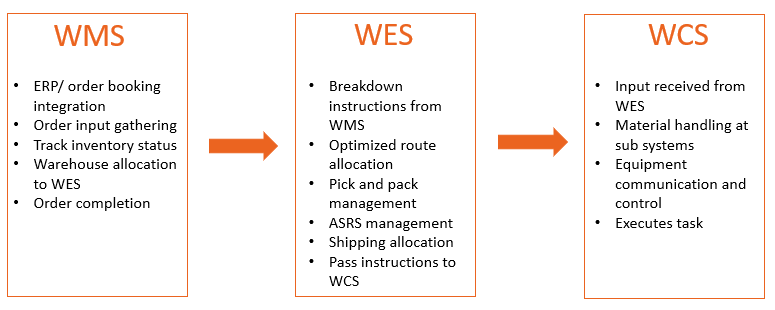

A warehouse with large-scale operations can benefit from investments in a WMS, WES and WCS.

The WMS operates at the warehouse level to process orders and balance the load by taking important decisions on aspects such as freight forwarders, the location and shipping line. Control then shifts to a WES, which breaks down these decisions into instructions for each line, such as the dock and packaging line to use. From here, the AS/RS takes over when it receives the instructions on which barcode to pick up and which packaging and shipping line to forward to. A WCS can convert the SKU details from the AS / RS to machine instructions that decide which robot will be involved in the picking process. A typical scenario plays out as follows –

In this way, the three systems act in tandem to process orders productively in a warehouse.

Considerations for the buyers

It is not easy to decide on which systems or all systems to invest in for your warehouse. NextFirst experts suggest asking these questions to make an informed decision –

- Does the automation solution have a WCS? A WCS implies that the solution was designed with a warehouse in mind and not just manufacturing equipment. A WCS will address communication and integration aspects, critical considerations in a warehouse.

- Is the information exchange easy to integrate with the same and next level of the communications architecture? Decisions have to be made in real-time, and seamless information exchange is a prerequisite.

- A high-volume, fast-paced operation with a high degree of variety is likely to have an evolved WMS. Will the WCS integrate with the existing WMS?

Answers to these questions will point you in the right direction to take. Undoubtedly, a WMS, WES and WCS will help you address the demands of your supply chain and meet the exacting standards expected by your customers. However, take the time to understand the role of each system and how it will work in your operating environment and ensure the systems will align with your current and future goals.

To explore more about appropriate warehouse automation solutions suitable for your industry, reach out to info@nextfirst.com

Tags: Warehouse Automation