Robotic Case Packing (Stacking)

Robotic case packing is an automated system that stacks bins (or child parts) in a case using a vision-guided robotic pick-and-place solution.

Benefits

- Bins fed in any orientation will be recognized and picked in the appropriate manner

- Barcodes identify the bin variant and separate the bins according to the stacking matrix

- Top sealer accommodates variable case sizes (i.e. 9 SKUs)

- Delivers the required cycle time and throughput

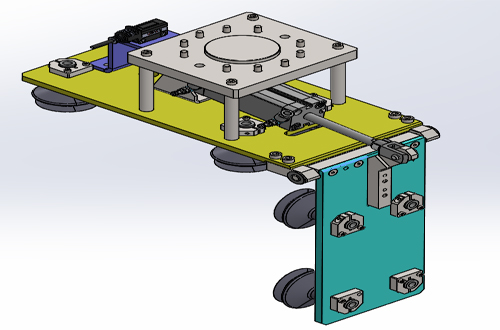

- Flexible End-of-Arm Tool (EOAT) is equipped with Vacuum and Bin Drop Detection unit

- AI and machine learning technology to recognize bins for all versions

- Creates a robot perimeter barrier with safety interlocking doors

- Low level tape detection

- Adequate conveyor path with a small footprint

- Fanuc 710ic (6-axis robot)

- Customized EOAT

- Compact conveyor path for less available space

Packaging line automation