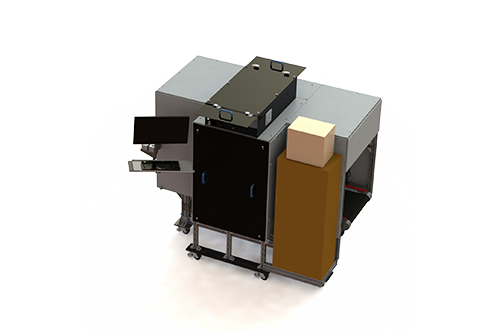

Hot Stamp Visual Inspection Unit

Hot Stamp Inspection is a unit that uses AI from a hot stamp machine to inspect products for multiple-sided defects and irregularities after hot stamping.

- Identifies the customer-specified surface flaws

- Provides feedback based on the type of defect and helps determine which parts are acceptable and which are not

- Improves quality as it allows inspection of defects from all four sides

- It is suitable for both automated and manual operations

- Minimizes inspection time

- Lowers cost of inspection

- Appropriate light effect for ease of inspection

- Used in a variety of settings regardless of light source variations

- Portable device that can be moved to the desired location

- Pneumatic-free system that only uses an electrical element

- Side panels allow for easy access to any maintenance

System Dimension

- (LxBxH) = 2m x 1.85m x 1.75m

(All the dimensions are in meter)

- Surface defect inspection